Oral Cryo

Oral Cryo

The oral cryotherapy device is a 2-part product containing a custom-designed mouthpiece and a water refrigeration unit. The device is used to cool down the mouth during chemotherapy, to prevent the onset of oral mucositis, a painful side effect of chemotherapy.

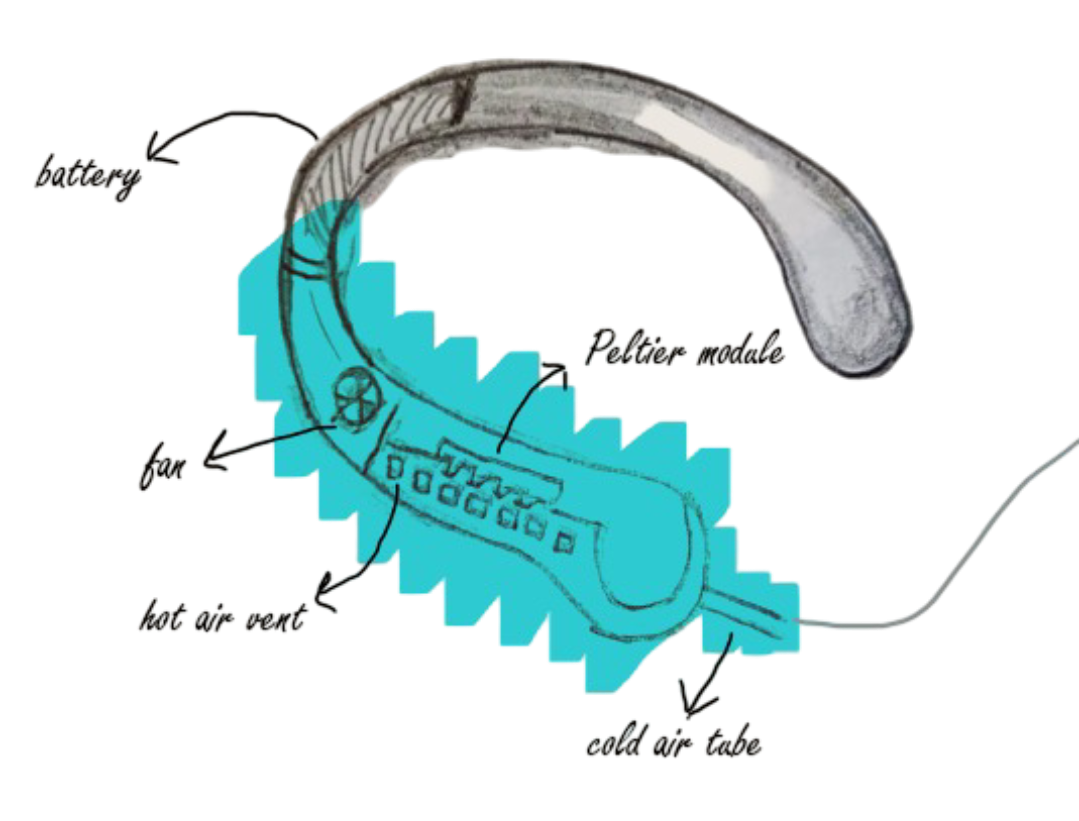

This project aimed to create a comfortable oral cooling device to help chemotherapy patients prevent or reduce oral mucositis, a painful side effect of treatment. The goal was to replace the current method of holding ice chips in the mouth during chemotherapy sessions. The initial concept used cold air as the cooling medium, where a fan would blow air over the cold side of a Peltier module and direct it into the mouth through a perforated mouthpiece, with the electronics housed in a neck-pillow-shaped casing. However, the Peltier modules couldn’t achieve the desired temperature of 6°C, prompting a shift toward more efficient cooling methods.

Design Journey

The next iteration explored a solid metal conductor cooled by dual Peltier modules in a headphone-style housing, powered by a pocket battery pack. While technically sound, this idea was shelved due to regulatory concerns over its novelty. To meet the company’s request for a more practical solution, a liquid-cooled system was developed, using a mini refrigeration unit to circulate chilled water through a custom-fit mouthpiece. After several design iterations, the final version—3D printed using Formlabs technology—was tested on volunteers, receiving positive feedback for comfort and fit. This individual professional project was completed at Croleon Innovations Pvt. Ltd under the supervision of Chinmay Deodhar, where I led all aspects of design, prototyping, and testing.